Extraction of Lithium from Continental Brines

Lithium is extracted from continental brines in a process that involves pumping brines into open-air ponds for evaporation. Currently, there are eight active facilities worldwide using this method, with more expected to join by 2030. The concentrated brines are then refined to remove impurities and Li2CO3 is precipitated. Freshwater is needed throughout the process for various purposes. The majority of non-LiCl salts in the brines crystallize and are considered waste.

Direct Lithium Extraction(DLE)

DLE (Direct Lithium Extraction) technologies are developed to address the environmental and economic challenges associated with evaporitic technology. The goal of DLE is to eliminate the need for open-air evaporation ponds. Various technologies have been proposed, such as ion exchange resins, thermally assisted processes, electrochemical methods, and more.

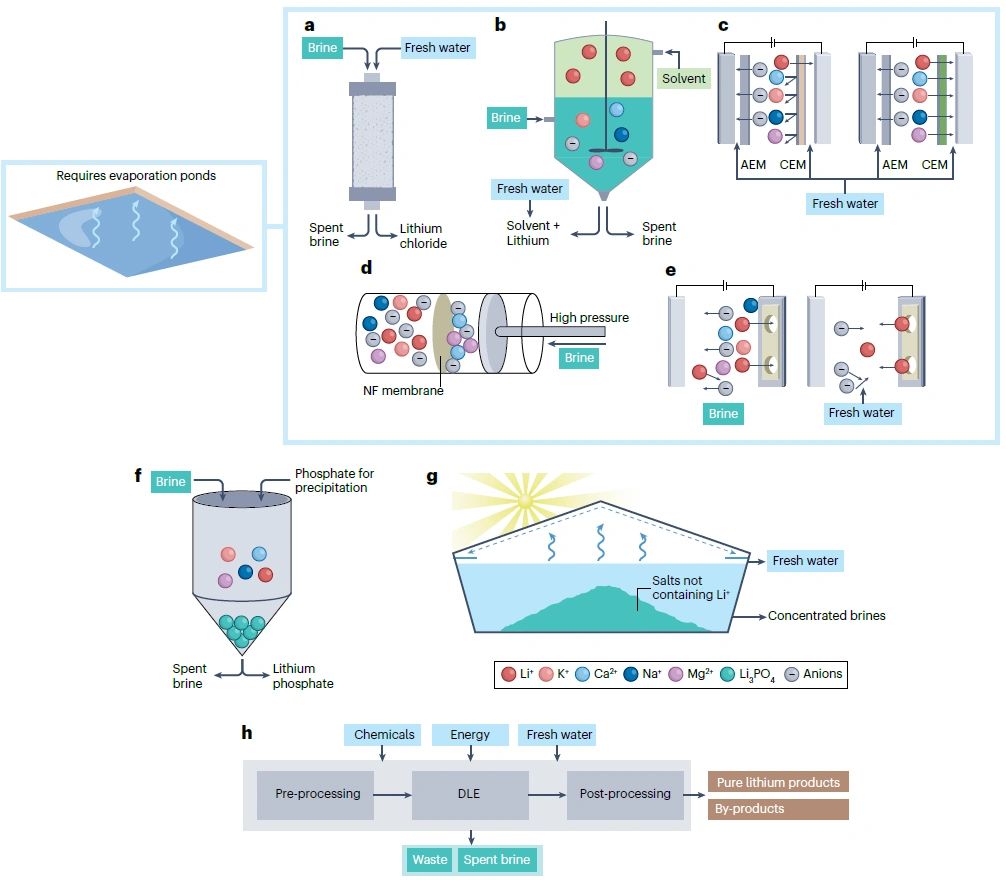

The working principles of DLE can be broadly categorized into seven main groups (see Figure below).

Direct lithium extraction (DLE) technologies, freshwater inputs and spent brine production. a, Ion exchange resins, also known as ion sieves or specific sorbents. b, Solvent or liquid–liquid extraction. c, Electromembrane processes with Li+-selective membranes (left) or permselective membranes (right) that are selective to anions or cations. d, Nanofiltration, NF. e, Electrochemical ion pumping, which is sometimes also termed electrochemical ion insertion or electrochemically switchable ion exchange. f, Selective precipitation of Li3PO4 via addition of Na3PO4. g, Thermal-assisted methods for brine concentration, other than open air evaporation. These methods include any type of evaporator, distillation device or membrane distillation. h, General scheme of DLE as part of an overall processing strategy. AEM, anion exchange membrane; CEM, cation exchange membrane.

Key Points

DLE technologies aim to address the environmental and techno-economic challenges of current practices by avoiding brine evaporation.

Several DLE technologies have achieved high Li+ recovery rates (>95%) and effective Li+/Mg2+ separation (>100) while employing zero chemical approaches.

However, most DLE experiments have been conducted on synthetic brines, overlooking the impact of multivalent ions or large Na+/Li+ concentration differences.

Certain DLE methods involve brine pH adjustments or heating up to 80°C, requiring energy, fresh water, and chemicals that must be considered in environmental impact assessments.

Future research should prioritize testing on real brines and achieving competitiveness across multiple performance indicators.

The environmental impact of DLE should be assessed throughout the entire process, from brine pumping to the production of pure solid lithium products.

Conclusion

Direct lithium extraction technologies offer promising alternatives to evaporitic methods, aiming to minimize environmental impacts. Further research and real brine testing are needed to fully understand the performance of DLE technologies and their competitiveness across various indicators. Assessing the environmental impact comprehensively is crucial to ensure sustainable lithium mining practices.

Extracted from: Vera, M.L., Torres, W.R., Galli, C.I. et al. Environmental impact of direct lithium extraction from brines. Nat Rev Earth Environ 4, 149–165 (2023). https://www.nature.com/articles/s43017-022-00387-5.